-

-

Follow steps as per Wear Tester -> Preparation of Specimen -> How to Prepare Specimen

-

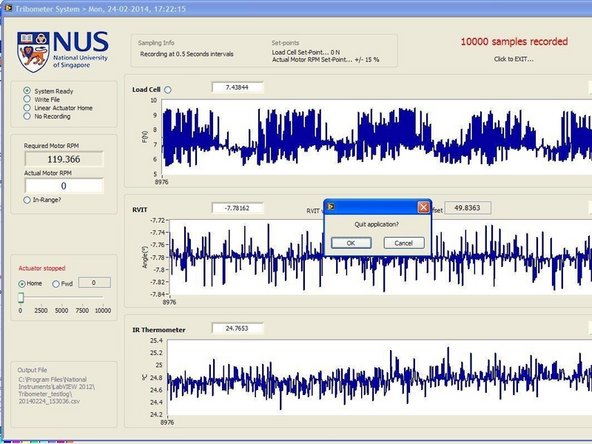

Obtain necessary readings before start of experiment such as:

-

1. Weight of ball specimen

-

2. Images of ball specimen, before and after cleaning

-

3. Images of disc specimen after cleaning

-

-

-

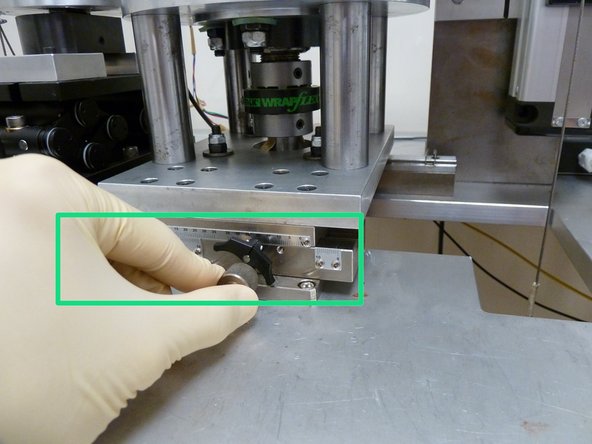

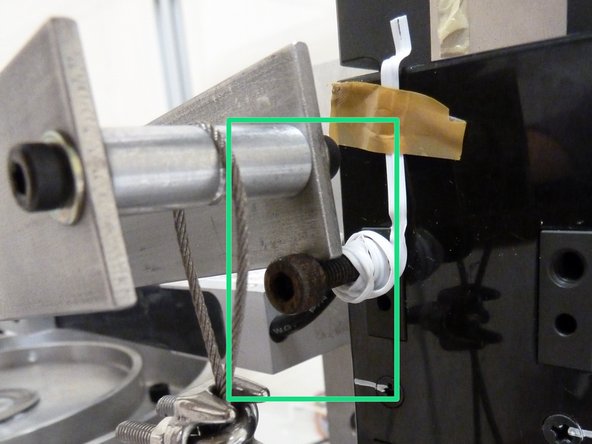

Slowly place ball/pin specimen in contact with disc. Make sure ball specimen is placed right on top of disc

-

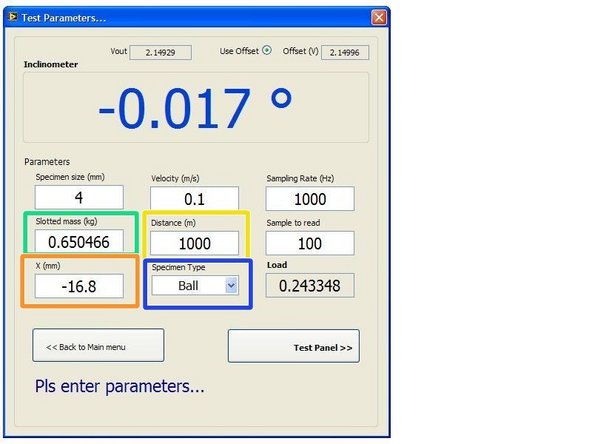

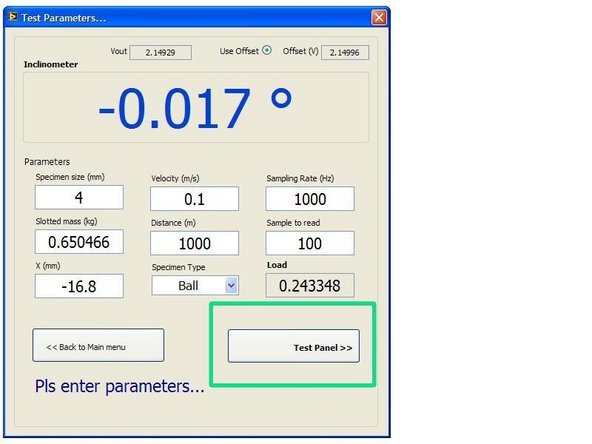

Now, adjust the lab-jack knob, while taking note of the inclinometer reading (in deg) on the 'Production Test' page, to as close to 0 degree as possible

-

Next, lock the lab-jack and place the cantilever back on the actuator step.

-

Almost done!

Finish Line