-

-

The screw is considered to be worn out if an allen key is unable to grip onto the grooves on the screw head, resulting in the screw not rotating with the allen key.

-

-

-

As drilling of the screw is to be carried out, the component which the screw is on should be removed from the tribometer for easier drilling.

-

If the component cannot be removed from the machine, try to at least remove any components for easy access to the stripped screw.

-

-

-

If the component can be removed from the machine, make use of one of the drilling machines available in the fabrication support centre at E3-01-01 for drilling.

-

If the component cannot be removed from the machine, use a hand drill available in the lab for drilling.

-

After drilling the through hole, the remaining parts of the screw can easily be swept out.

-

-

-

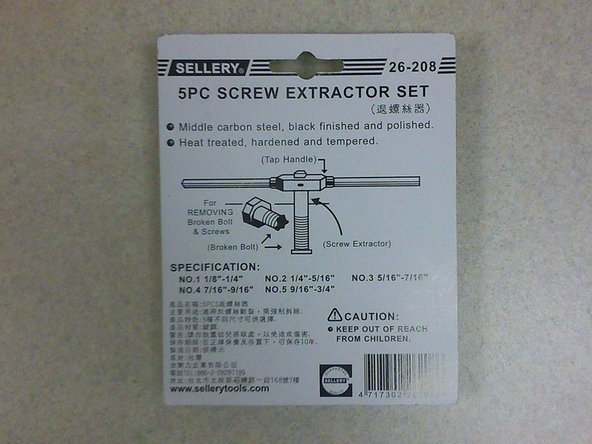

A screw extractor is a counter-clockwise drill bit which can be used to forcibly rotate the screw in a counter-clockwise direction, thereby loosening it.

-

A hole of at least 0.5 cm depth has to be drilled onto the screw head before attempting to use the screw extractor to remove the stripped screw.

-

-

-

Do not over-tighten any screws as friction between the allen key and screw head can wear off the grooves on the screw head.

-

Use an allen key made from stainless steel rather than mild steel as a worn out mild steel allen key can cause the grooves on the screw head to be deformed.

-

The video shows the over-tightening of a screw. The distinctive sound made by this process serves as a signal to STOP further tightening of the screw.

-

One Comment

Admiring the worn-out screw head aesthetics! At JF Engineering Products LLP, we specialize in manufacturing Monel 400 Hex Bolts that not only withstand wear but also exemplify precision and quality.

Deepak Chandan - Resolved on Release Reply